Why is Gore dropping Shakedry – and what does it mean for your outdoor gear?

News from a leading waterproof fabric manufacturer could be music to the ears of environmental campaigners – or is it?

No sooner (or so it seems) that Gore reveals a revolutionary waterproof and breathable membrane, Shakedry – such as used in R7 Gore-Tex Shakedry Trail Hooded Jacket – and there comes news that it is being dropped by the leading waterproof membrane manufacturer.

Apparently there is still a stock of Shakedry material, launched in 2016, being used by some clothing brands, especially those in the cycling apparel world, but Gore is no longer making it.

The change of heart appears to focus on the use of chemical baddies PFCs (perflourochemicals) and Gore-Tex’s bid to become generally more environmentally friendly. I wonder what this move away from waterproof materials that use PFCs will mean for outdoors apparel brands more widely – and how it will affect us, the consumers, as well as the benefits for the environment, humans and animals.

Back to basics: what are PFCs?

PFCs are a class of synthetic chemicals, and the name is an umbrella term for other man-made chemicals, including PFOS (perflourooctanoic sulfonic acid) and PFOA (perflourooctanoic acid).

PFCs are made of short or long chains of carbon atoms, capped by fluorine. If you put a chain of carbon atoms together and add fluorine atoms on the ends, an unbreakable bond is created. This means that PFCs are made to last and do not biodegrade, which is why they are sometimes called 'forever chemicals'.

PFCs are also highly effective at repelling water, oil, stains and heat. It’s the water repellency that has historically made them so attractive to the outdoors industry especially for making waterproof jackets, boots and other gear, such as tents.

The history of PFCs

In 1954, the world saw the first wide-scale use of PFCs in the shape of non-stick Teflon pans. Since then, PFCs, including PFOS and PFOAs, have been used in plastic, clothing, food packaging, electronics, personal care products, firefighting foams and medical devices, among many other products.

Advnture Newsletter

All the latest inspiration, tips and guides to help you plan your next Advnture!

In the outdoors industry, PFCs have long been used in the making of fabric that needs to be durable, highly waterproof and breathable, such as for jackets, boots and tents. This happens in two ways.

First, membranes, such as Gore-Tex and eVent, which are layered with fabrics to make the product waterproof, have historically been made mainly made from PTFE. These require PFCs in their production.

The other use of PFCs is in durable water repellent (DWR) treatments. Textiles and membranes are given a coating, or finish, to ensure that water and dirt beads on the outside of the product rather than soaking into the fabric. Some sprays and washes used for re-waterproofing clothing may also contain PFCs.

What’s wrong with PFCs?

While PFCs have long been seen as highly useful across many industries, they are also potentially harmful to the environment, as well as the health of people and animals. The chemicals are are also highly persistent, which means they stay in water systems for decades. There have been reports of measurable levels of PFCs in snow, ice and water, even as far afield as the Arctic.

It’s now claimed by scientists that almost every living being on earth has some level of PFCs in their blood. Some studies suggest it's possible to detect PFAS in 99% of people tested. Others have found PFAS in wildlife, including polar bears, dolphins and seals. And because PFCs have a half life of three to four years, they take a long time to leave the environment and your body.

It’s not yet known what this figures mean to health and at what levels they are dangerous. However, there have been studies that claim the chemicals cause health issues, such as some forms of cancer, as well as other health concerns.

Thus, it is widely agreed that PFC use is generally unfavorable and should be avoided if possible.

Campaigns to reduce PFC use

Across many industries there is increasing pressure both legally and from consumers for a reduction in the use of PFCs. For example, Greenpeace’s Detox Outdoor campaign, which started in 2017, put the spotlight on the outdoor apparel sector and called for an elimination of PFCs.

It was reported by Greenpeace in 2017 that some brands had made commitments to go PFC-free. They included Gore, the maker of Gore-Tex products, as well as Paramo, Rotauf and Vaude.

Others followed, but pledges to commitments does not mean companies actually make the changes. Also, there are two strands to the commitments, focusing on general PFC use in the production of membranes and textiles, as well as DWR treatments.

Indeed, a report in February 2022 by alternative consumer watchdog Ethical Consumer revealed that of 29 outdoor apparel companies assessed, including many major brands, only four did not use any PFCs. They are Páramo, Vaude, Alpkit and Fjallraven.

Over half of the 29 reportedly had no phase-out date for their use of PFCs, 86% of companies were still using PFCs at the time of the article and four companies were not even acknowledging the issue.

This is the PFC-free ratings in Ethical Consumer’s outdoor clothing guide:

Best: Páramo, Vaude, Alpkit, Fjallraven.

Middle (using PFCs but target date for phase-out): Rab, Lowe Alpine, Berghaus, Jack Wolfskin, Patagonia, North Face, Decathlon, Mountain Warehouse, Mammut.

Worst (using PFCs and no phase-out date): Haglofs, Montane, Columbia, Mountain Hardwear, prAna, Mountain Equipment, Sprayway, Ayacucho, Craghoppers, Regatta, Coleman, Marmot, Rohan.

Worst (using PFCs and no information on PFC policy): Trespass, Gelert, Karrimor, JD Sports (Peter Storm etc).

It’s important to note that plenty of brands now use PFC-free DWR, but may well still use PFCs in other part so the production process.

Let’s take a closer look at Gore-Tex

Since many outdoor clothing brands use Gore-Tex membranes for their waterproof apparel, footwear and gear, it’s a good company to focus on when considering the reduction in the industry use of PFCs. Plenty of outdoors enthusiasts also consider Gore-Tex to be the ultimate membrane for protection in tough weather conditions. There are different types of Gore-Tex for different uses.

There have been changes over the years to the way Gore-Tex is made and the use of PFCs. And, note, this is where the topic starts to get rather confusing.

We need to go back to the beginning to try to understand the PFC impact of Gore-Tex.

It all started in 1938 when American multinational chemical company DuPont discovered PTFE, which was described as a strong, synthetic polymer. It went on to be used in many industry and domestic applications, from valves and seals to kitchen cookware, such as the non-stick Teflon pans mentioned earlier.

Then came the discovery of expanded polytetrafluoroethylene (ePTFE) by Gore in 1969. The company's chemists took polytetrafluoroethylene (PTFE) and created e expanded PTFE, or ePTFE. This ePTFE went on to be used in many products, from guitar strings and cables to waterproof jackets and boots.

For decades, creating ePTFE membranes required the use of PFAS chemicals, which you’ll remember are part of the larger group of PFCs.

In 2017, when agreeing to reduce the use of PFCs with Greenpeace, Gore announced that “PTFE is not a PFC of Environmental Concern”. Indeed, Greenpeace agreed with the claim that PTFE is safe and environmentally sound. The explanation was that "PTFE is a fluoropolymer that is highly stable, too large to be bioavailable, insoluble in water, and does not degrade in the environment. Therefore, it is not a PFC of Environmental Concern and it does not degrade into them."

Yet, still PFCs continued to be used in the DWR when creating waterproof products made by and from Gore-Tex.

Next came a new pledge by Gore. In 2018, Gore introduced fabrics for Gore-Tex garments with a PFC-free DWR treatment. Of course, it’s important to note that any brand making use of Gore-Tex in their products can also choose to use a PFC-free, or not, DWR on the exterior of the waterproof jacket.

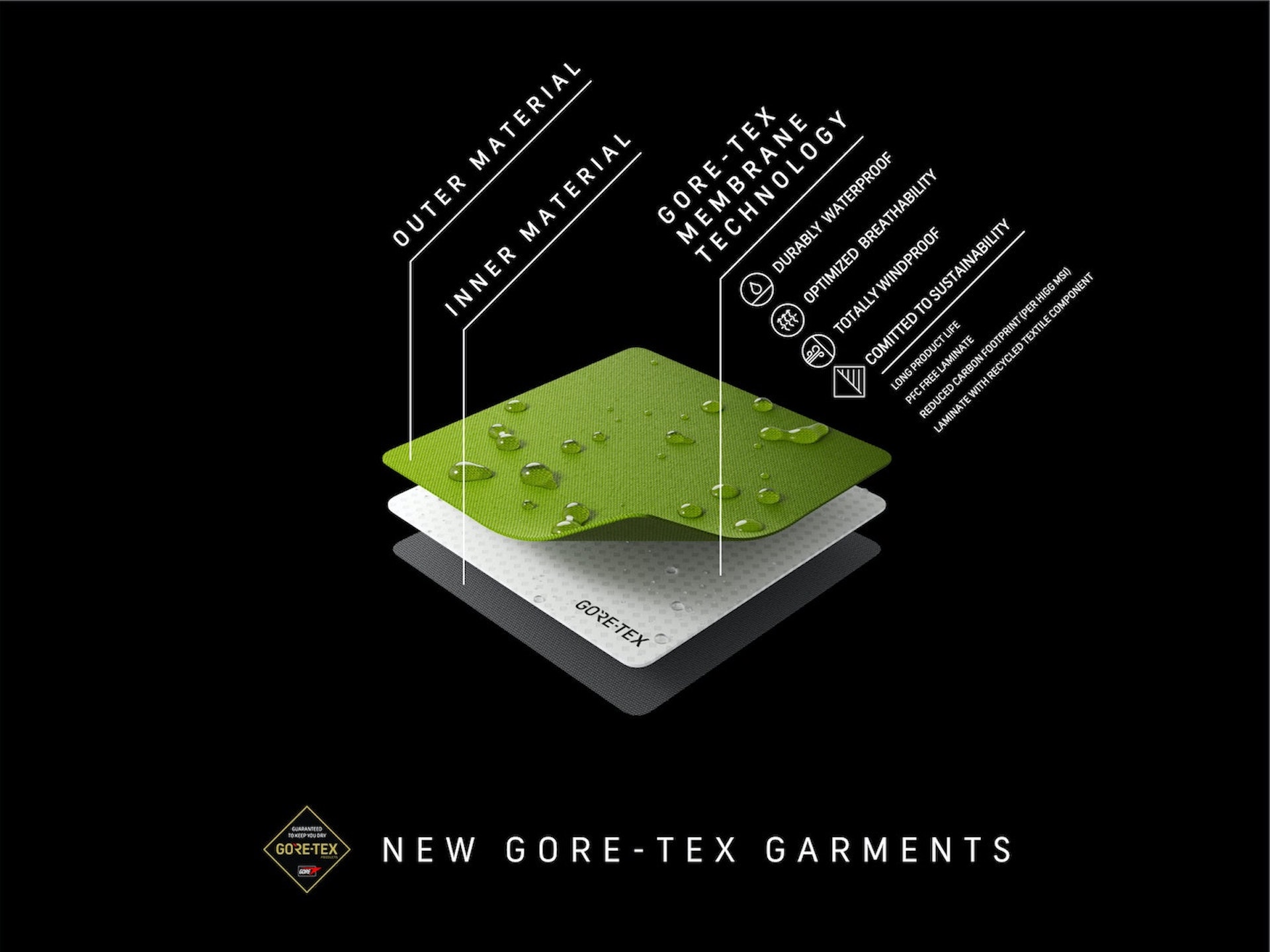

Another big announcement came in the autumn of 2021 when Gore launched a new waterproof membrane technology that was said to be free of PFCs. It was further revealed that the “more ethical fabric” should be making its way into clothing products by 2022/2023.

The new ePE membrane, 12 years in the making, is made with a non-fluorinated process and without PFAS (per- and polyfluoroalkyl substances). It also uses less material – so that means it uses less plastic in production – than previous waterproof Gore-Tex membranes.

The first products using this new PFAS-free membrane should be available soon, although the were meant to be ready for the end of 2022 according to various reports.

Gore has not yet publicly committed to eliminating all PFAS from manufacturing Gore-Tex.

So, how does ePE work?

Materials like ePE have long been available to the outdoors industry as microporous polyethylene (PE) textiles. But companies such as Gore have not been keen to use this historically because they claim it lacks the durability needed for high performance waterproof clothing.

Instead, Gore-Tex has developed PE by using “expansion” technology and combined it with polyurethane (PU). How this happens is that, first, the PE material is expanded to create billions of tiny holes in it. The holes allow vapour to pass through yet still maintain a high strength-to-weight ratio.

Next, PU is added to create a breathable but waterproof membrane. It’s also only half the thickness of Gore-Tex’s current waterproof membranes. The new ePE material is then bonded as a laminate to a backer or face layer to create waterproof and breathable materials for use in products such as waterproof jackets and waterproof trousers.

It’s much like the Gore-Tex fabrics we all know about but made using different ingredients. So if this membrane works, why hasn’t this method been used before?

Until there are more products on the market that use the new ePE membrane we won’t know if it’s as good as Gore-Tex of old. However, Gore-Tex’s own performance ratings look very positive with excellent waterproofing, breathability and wind-proofing ratings claims.

As to why this material has not been used before is probably because of how historically well Gore-Tex membranes of old worked and because developing new products takes time and money.

More about the performance of ePE

Take a look at the Gore-Tex website to see the company’s description of their Gore-Tex ePE: “The membrane is light, thin, yet strong, and it's PFC free* with a reduced carbon footprint**.

“To form a GORE-TEX product the membrane is combined with carefully selected textiles such as recycled, solution or undyed textiles***.”

There are a few caveats so let’s look further:

* Advances Gore Fabrics´ goal of being free of PFCs of environmental concern over the lifecycle of its consumer products. In this case, the goal is accomplished using non-fluorinated materials.

** Through laminates with a new lower-mass membrane and select textile(s) (per Higg Materials Sustainability Index tests)

*** Depending on laminate choice.

The ePE production is a non-fluorinated process and, so far, ePE has achieved OEKO-TEX’s STANDARD 100 certification. In addition, according to Higg Materials Sustainability Index tests, ePE beats the polymers it replaces in terms of carbon footprint.

The first brands that plan to make use of the new ePE fabric are reported as including adidas, Arc’teryx, Patagonia and Salomon, among others.

Are there other PFC-free options for outdoors products?

As the Ethical Consumer report revealed, there are brands, such as Fjallraven, of Sweden, which are making big strides to become PFC-free.

Take Fjallraven as an example. While the company does admit that their PFC-free materials do not have the waterproof durability of alternatives containing PFCs, they encourage consumers to treat jackets etc with PFC-free re-waterproofing sprays.

As an aside, it’s good to know that Nikwax, which makes products that re-waterproof and clean outdoor gear, does not use fluorocarbon-based water repellency.

Páramo is another with a gold star for being PFC free, or, as “PFC as we can be” they report. A statement on the brand’s website says that “no PFCs are used in the manufacture of a Páramo product. But [...] PFCs are now so widely dispersed in the environment that even the tap water we drink has a low level of background pollution. This level of contamination unfortunately cannot be avoided.”

Páramo’s threshold limit for the presence of fluorine on fabric is 0.007% by mass. Any fabrics which do not pass this test are rejected and sent back to the supplier. In addition, all new Páramo water-repellent products carry a guaranteed PFC treatment free label.

Alpkit reveals that after years of working towards a PFC free goal all their waterproof jackets are now completely PFC free.

Meanwhile, Vuade has developed what they call Ceplex Green membrane, which is completely free of PFCs.

Another brand of note is tent manufacturer Nemo. In 2022, Nemo launched a fabric in a few of their best-selling tents that is made from 100% recycled fabric and doesn’t contain harmful flame-retardant chemicals or fluorinated water repellents.

How did they do this? They use a tight nylon and polyester weave called OSMO that they claim is better at repelling water, dries quicker and stretches less when wet when compared to more traditional fabrics using PFCs. Look for current products, the Dagger and Hornet tents – and hopefully wider use of OSMO from this year.

Then there’s eco-friendly leader Patagonia, which says it has developed its own environmentally friendly polyester-based version of Gore-Tex made with 100% recycled fabrics. This has been used in Patagonia’s Infurno winter jacket, which is also lined with post-consumer recycled soda-bottle fleece. They also use a PFC free DWR.

A fabric called eVent BIO is claimed to use "highly renewable and smartly sourced castor bean to create a light, tough and flexible membrane that offers protection against wind, rain and snow in a highly breathable laminate."

The fabric-making company eVent also states: "We use recycled face fabrics and backers paired with C0 DWR technology to create a PFC-free 100% waterproof and windproof fabric technology."

Note, this author tried to find information about whether eVent Bio has been scrutinised for PFC-free claims but nothing seemed apparent.

And then came the Shakedry news

As we have written, Shakedry fabric has a membrane that contains PFC chemicals and Gore has stated it won’t be making the material any more. The move appears to underline the company’s commitment to reduce PFCs in manufacturing, including the new ePE membrane, as it bids to become completely PFC-free.

Do we actually need PFC fabrics?

For many people, Gore-Tex has become the fabric of choice when buying high performance waterproof and breathable outdoor apparel. It’s long been tested and hailed as the best way to stay warm and dry in tough conditions the outdoors. But is this perhaps a myth?

According to Ethical Consumer many of the brands still using PFCs for waterproofing said they needed to continue to do so because alternative options haven’t yet been found that provide the same performance and durability.

This was questioned by the watchdog because Greenpeace scientists claim good satisfaction levels when wearing Páramo clothing, which is PFC-free. Páramo was used by scientists as part of the British Antarctic Survey team.

There other brands that claim good waterproofing from PFC-free products, such as eVent, and you will find out about how these perform through personal recommendations and waterproof jacket reviews, etc. You are warned to beware of greenwashing issues, too.

And then there is a whole other discussion about what happens when products don’t degrade. Think about the ePTFE membrane, for example, which, according to Gore, "is inert, insoluble in water, extremely stable and not biodegradable. Therefore, it does not degrade to become a source of PFCs of environmental concern". If the fabric won’t break down and it ends up in landfill, that’s clearly another environmental concern. But this is a topic for another time...

What will it mean for us as brands go PFC-free?

On the face of it, it’s good news that more and more outdoor clothing and footwear brands are committing to being PFC-free both in their production processes and with DWR treatments.

Its is also worrying that some companies appear to be ignoring the issue.

However, there is also the balance of consumer costs. Many of the newer PFC-free products are expensive and this may end up precluding people from enjoying the benefits of spending outdoors while staying warm and dry.

Another consideration is to try to keep your current waterproof product going for as long as you can. It has already been made and even if it has been manufactured and the longer you care and wear it, the better it is for end-of-product-life waste.

If you do need a new garment, it is worth considering brands that do not use Gore-Tex at all and have their own PFC-free pledges. Also look for products that have PFC-free DWR at the very least.

In the future, we can also look towards more developments, such as Gore-Tex’s ePE membrane, that pledges to reduce the PFC chemicals that were once hailed as magical and now are castigated as being toxic and harmful to the environment, people and animals.

- Best waterproof jackets: stay dry and comfortable in wet weather

Fiona Russell is a widely published adventure journalist and blogger, better known as Fiona Outdoors. She is based in Scotland and is an all-round outdoors enthusiast with favorite activities including trail running, mountain walking, mountain biking, road cycling, triathlon and skiing (both downhill and backcountry). Aside from her own adventures, Fiona's biggest aim is to inspire others to enjoy getting outside and exploring, especially through her writing. She is also rarely seen without a running skort! Find out more at Fiona Outdoors.