I got soaked at Decathlon HQ to learn how the French brand tests its tents

Decathlon’s design and testing process involves listening to consumers, extensive prototyping and a lot of water

Chamonix has long been heralded as the epicenter of the European outdoor scene. It’s home to some of Europe’s highest mountains and world-class ski resorts, and the mountain village even serves as the starting point of the Ultra Trail de Mont Blanc – the most prestigious trail running event in the world.

It’s no surprise, then, that French sports powerhouse Decathlon has made Chamonix the home for all of its outdoor brands. It’s here, in a workshop just out of town, that they design everything from hiking boots and backpacks to trekking poles and tents; all before testing everything they make in the breathtaking mountains that encompass this vibrant mountain location.

It goes without saying that when I was invited to visit their facility earlier this year, I jumped at the chance to see where Decathlon designs all of their tents – and to investigate first-hand just how they ensure their designs are sound.

Meet the expert

Craig loves nothing more than pitching up in the backcountry, preferably while taking on a long-distance thru-hike. His adventures usually take place in the hills and mountains of Wales but he occasionally gets away to his beloved Alps. As one of our expert campers, Craig revels in testing camping equipment and knows a sturdy shelter from on that will give up the ghost when conditions become challenging.

Decathlon’s Mountain Store

To find out all about how Decathlon designs and tests its tents, I headed to Chamonix during a late spring snowstorm to visit the brand at its purpose-built outdoor workshop.

Located in Passy, a short drive out of Chamonix, this compound is home to 550 team members and acts as a hub for worldwide teams of engineers, designers, product managers and sportspeople. Known as the Mountain Store, the facility is an ultra-modern design-and-testing playground built to impressive sustainability standards; the perfect place for the world’s biggest sports retailer to bring their boldest outdoor gear ideas to life.

The Co-Creation Platform

Working towards their overall goal to ‘move more people through sport’, products go from first conception through to prototyping at the Mountain Store, with most coming to life thanks to Decathlon’s Co-Creation Platform. This purpose-built tool allows them to speak directly to up to 220,000 active sportspeople, outdoor enthusiasts and industry pros. It gives Decathlon’s design team direct insight into what people need, the challenges they need to solve and the type of products they’re looking for.

Based on this information, Decathlon is able to work on designing the exact products end-users want – even if some ideas might initially sound a little crazy. When it comes to tents, this has resulted in designing shelters that are quick and easy to pitch (such as the famous Quechua 2-Seconds tent which pops into life at the press of a button), the UV-resistant Fresh&Black range, or the recent ‘Skyview’ line, which allows you to properly sleep under the stars (thanks to a retractable blind that you can pull back over a transparent ceiling).

Advnture Newsletter

All the latest inspiration, tips and guides to help you plan your next Advnture!

Prototyping

Once a specific need has been identified, the team gets to work building early prototypes. This process, which may involve numerous teams of engineers, seamsters and interactive designers for 3D demonstrations, is all conducted on-site inside Decathlon’s Mountain Store.

Once they have an idea that’s functional and solves the specific problem they set out to address, Decathlon claim to work to reduce the product's environmental impact as much as possible – long before the initial prototype even gets a whiff of the outdoors. This is all to ensure that everything Decathlon sells is minimally harmful to the environment, working towards the goal of reducing their carbon emissions by 20% by 2026 (in comparison to 2021 levels).

As a part of this, Decathlon pays a lot of attention to the repairability of every item the team designs. That means that tent poles should be replaceable, seams stitchable and zips repairable. The thinking is that a product that needs to be fully replaced at the first signs of wear and tear is always going to be more harmful than one you can fix, regardless of the production practices.

The tent rain-testing facility

Once an initial concept has been designed and its eco-credentials have passed Decathlon’s tests, it’s then on to testing, which was the part of the tour I was most excited about. To experience this first-hand, we left the Mountain Store and went on a short drive up the valley – and straight into an old abandoned car yard.

In stark contrast to Decathlon’s ultra-modern outdoor design hub, their testing facility is much less glamorous. A singular gray unit surrounded by the remnants of countless rusty Renaults, the whole place felt more like the type of secret lair you’d see in a James Bond movie rather than the proving ground for Decathlon’s long line of tents.

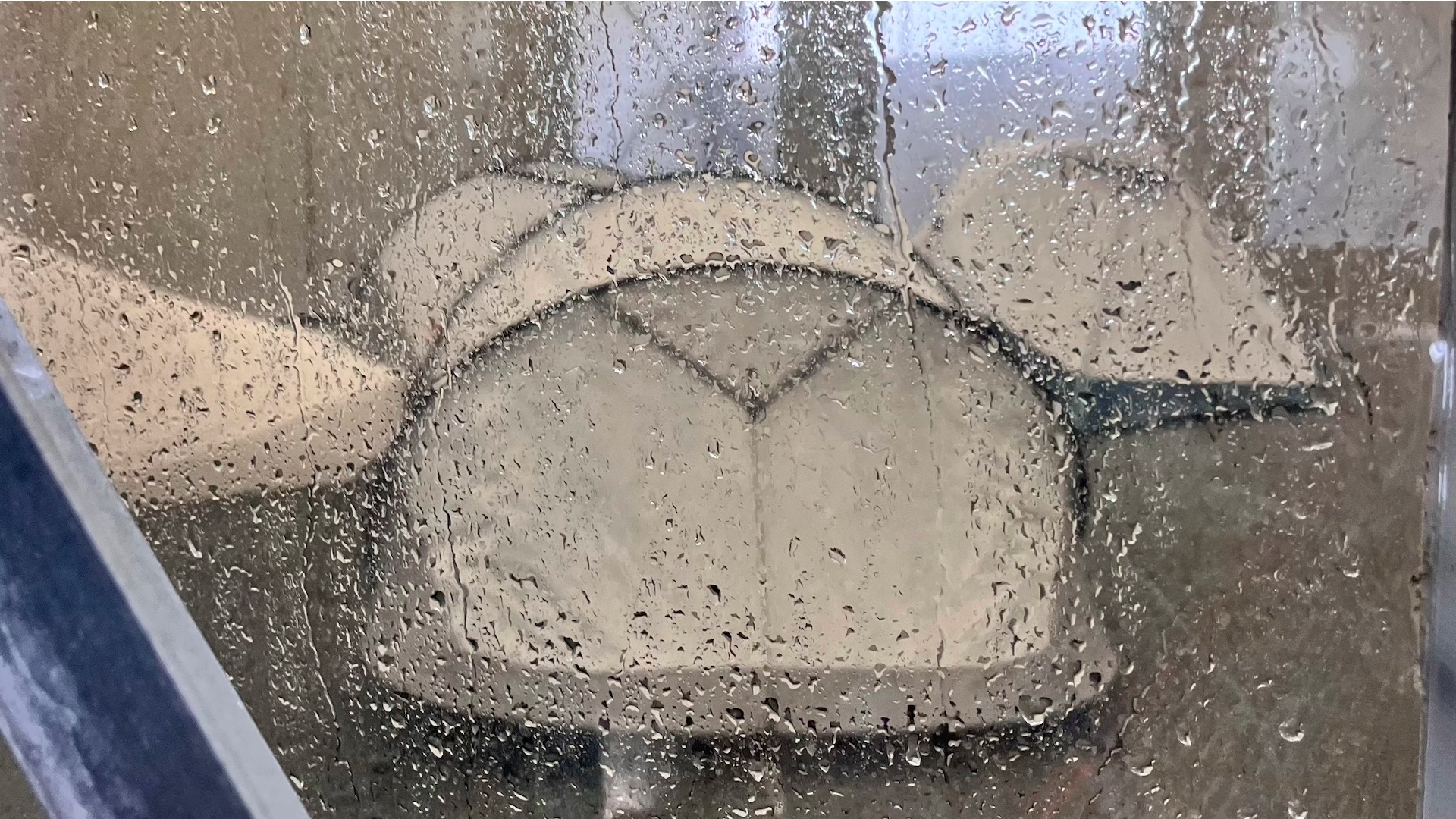

But lo and behold, once you squeeze through the solid metal door, you find a mind-bending array of pipes and taps wrapped around a huge transparent PVC cube.

Rain testing procedure

To rigorously put their prototypes up against exaggerated real-life conditions, all of Decathlon’s tents are pitched on a platform underneath regimented rows of shower heads. Here, they’re pummelled with rain for a minimum of three hours.

The approval process is then a simple one: if there’s a single drop inside, the tent has failed and it’s back to the drawing board. But if the inside has remained bone dry after three hours under intense rain, it’s a pass and the tent goes on to the next phase of the design process.

To ensure the tents will perform optimally in the real world, however, Decathlon doesn’t hold back. They soak each shelter with 200 liters per hour per meter squared.

To put that in perspective, a sustained rainstorm that produces 50 liters per hour per meter squared is considered a 1-in-100-year event in the UK, which equates to only a quarter of what Decathlon tents are put up against. 200 l/h/m² is more like your shower at home, which vastly outdoes anything you’ll (hopefully) ever experience in the great outdoors.

What does this much rain feel like?

To my delight, I was invited to jump in a Decathlon tent during one of their regular rain tests. Having already witnessed a few drenchings from the viewing platform, I was excited to see what this was like from the inside.

And better yet, I got the chance to experience this from inside a Forclaz MT900 Trekking Pole tent, a model I’m already very familiar with. I’d previously reviewed a sample for this very website and remained impressed by its weight, price and performance. I’ve also used it several times in very heavy British rain, so I already had many real-life benchmarks to compare the experience with.

The second the taps were opened, the whole tent started to shake under the weight of the rain, and the noise was more akin to an aeroplane taking off than to camping in a sudden onset of rain. From inside the tent, you could see giant water droplets sliding off the fly and numerous channels quickly developed in the material. It was like sitting under a spontaneous network of emerging rivers that funnelled water into thick waterfalls at the foot of the flysheet.

Thankfully, the MT900 did its job valiantly and kept me completely dry inside. Even after around five minutes not a single droplet had penetrated the flysheet, which gave me renewed confidence in my own version at home.

Real-life rain tests

For Decathlon, this rain test is a crucial part of the tent design process. If any water makes it in, the tent is immediately sent back to the drawing board. If it remains dry inside, however – as the MT900 Trekking Pole tent did for me – it’s ushered on to the next round of the design process.

As a part of this, prototypes get sent out to individuals signed up to Decathlon’s Co-Creator Platform who then test these items in rigorous real-world environments. For tents, this means weeks of testing on real adventures, being used on long-distance treks, overnighters, and climbing trips in the glorious mountains that surround Decathlon’s Mountain Store.

Testers then give feedback not only on the tent’s performance in wind and rain, but on the small details that can make or break an experience. If necessary, this feedback results in further iterations and design tweaks, before a renewed round of testing begins. Then – if the tent performs well and the feedback is positive – the product will slowly start making its way onto shelves across the world.

After the rain test, we headed back to Decathlon’s Mountain Store for a final recap and a walkthrough some upcoming products. And with that, my tour was over. For me, that meant heading back to the UK with renewed confidence in my growing collection of Decathlon tents – and with an unusual amount of excitement about the prospect of camping in the rain.

- How to stake a tent the right way

Growing up just south of the glorious Brecon Beacons National Park, Craig spent his childhood walking uphill. As he got older, the hills got bigger, and his passion for spending quality time in the great outdoors only grew - falling in love with wild camping, long-distance hiking, bikepacking and fastpacking. Having recently returned to the UK after almost a decade in Germany, he now focuses on regular micro-adventures in nearby Snowdonia and the Brecon Beacons, as well as frequent trips to the Alps and beyond. You can follow his adventures over on komoot.